About the development of our Flip

What is a flip ?

Flips or lens holders are a nice-to-have accessory when you do macro shooting underwater with a wet lens as it will allow to switch quickly from shooting with or without a macro lens without having to unscrew and store the lens. The macro lens is simply screwed on a lens support that is toggled against the housing port when needed. It also allows for big ports or those without thread to mount and use wet macro lenses.

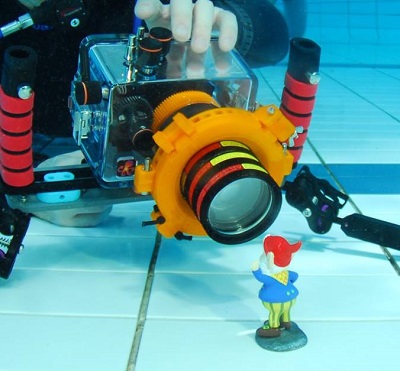

The flip in action and mounted on a port without thread.

Back in time

I actually don't remember well why I bought my first 3D printer years ago apart from a need for some custom small parts for my electronic projects. I remember about that technology in a major newspaper in the readers' comments about the future of paper but it's during my second stay in Lembeh Strait that I came across one of those 3D printed flips from a well-known brand and 3D printed. Monthes later, when I switched to a new set of video equipment, one of the first real product was a flip for a 4 inches Ikelite port.

Gen 1: The ancester

Five generation of products to date

Thinking back, this first flip was bad in many aspects but it was normal: it was the first and it was designed by someone who had just started into 3D design, with a low grade printer and badly calibrated. Today, EOCEAN flips are in their fifth generation benefiting from the lessons learnt from each previous generation.

First generation

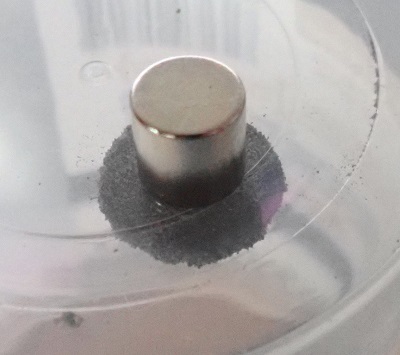

The first generation had too thin hinges and a locking screw that was also destroying those hinges without locking anything. The first design might have resisted for a few dives before breaking. This flip used magnets encased into polyurethane cement. They quickly rusted. The use of magnets has been banned for me because apart from interfering with the navigation compass, in remote volcanic locations, bottom sand is charged with iron particles and they will interfere with any magnetic attachment system. Submerged EOCEAN products do not use any magnets. No metallic parts will rust thanks to marine grade stainless steel parts.

In volcanic areas such as Lembeh Strait, sand will love any nearby magnet.

Seconde generation

The second generation use paracord to maintain the lens holder against the port. This design has not changed since then but in summer 2018, a part was added for divers with thick gloves to allow a better grip of that cord. This generation introduced a generic design which will allow a quicker development of flips for more housing brands. Flips can be designed quickly to other housings even if they are not in the online catalog.

Gen 2: Magnets are history but the locking screw is still useless.

Third generation

The hinges are improved but the locking screw was still useless for the second generation. The third generation will introduce a solution that will no longer destroy hinges (unless in case of excessive tightening). The locking screw was the first major improvement as it is now possible for the port to have a clear view when the macro lens is toggled off without having in dangling when shooting toward the bottom. A feedback from a user will lead to redesign the screw cap for a softer touch. Comments, even minors, from real-life use from customers are taken into account to improve products.

Gen 3: Rise of the useful locking screw.

Fourth generation

One common issue from previous generation was the use of polyurethane cement to lock the aluminum threaded part to the lens holder in plastic. The mix was not good and sooner or later, with seawater and vibrations, the aluminum part was going loose from the plastic holder with some potentially losses of lens.

Some brands bypass this issue by attaching the support directly around the lens rather then using the threaded ring option. This choice has the advantage to secure the lenses to 1 or 2 but the compatibility is limited to lens more or less the same exterior body diameter rather than allowing almost any lens with 67 or 77mm threads. This also limits the number of lens you can take with you on a dive (I take up to 6 different ones...). Polyurethane has been replaced by some stainless steel hardware.

Nowadays, EOCEAN no longer uses any sort of cement. It's better for the environment. The flip is safer for the precious optics it carries and its lifetime is increased.

Gen 4: No cement anymore !

Fifth generation

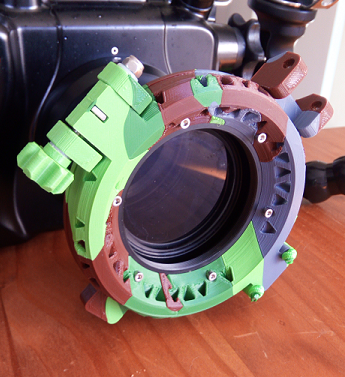

The fifth generation is the sum of all previous improvement with reinforced hinges, mastered machining process with quality tools and printing filament. This generation has introduced the "generic flip" tailored at almost any housings having a M67 or M77 thread. It is assembled with 35 pieces and the final assembly requires an hour of work in my workshop.

I wrote "almost any housings" as there are still some issues like Ikelite ports in M67 for which a dedicated model is still needed... for now.

Gen 5: the current generation

When EOCEAN became a business, all those developments have been applied to previous models. The initial model for 4-inches Ikelite port is still missing in the catalog but that will come.

Flips are available with 1 or 2 lens supports and may have different colors (our competitors do not offer this). They can be reinforced in carbon fiber. And as EOCEAN designs and sells its own products, they are less expensive.